描述

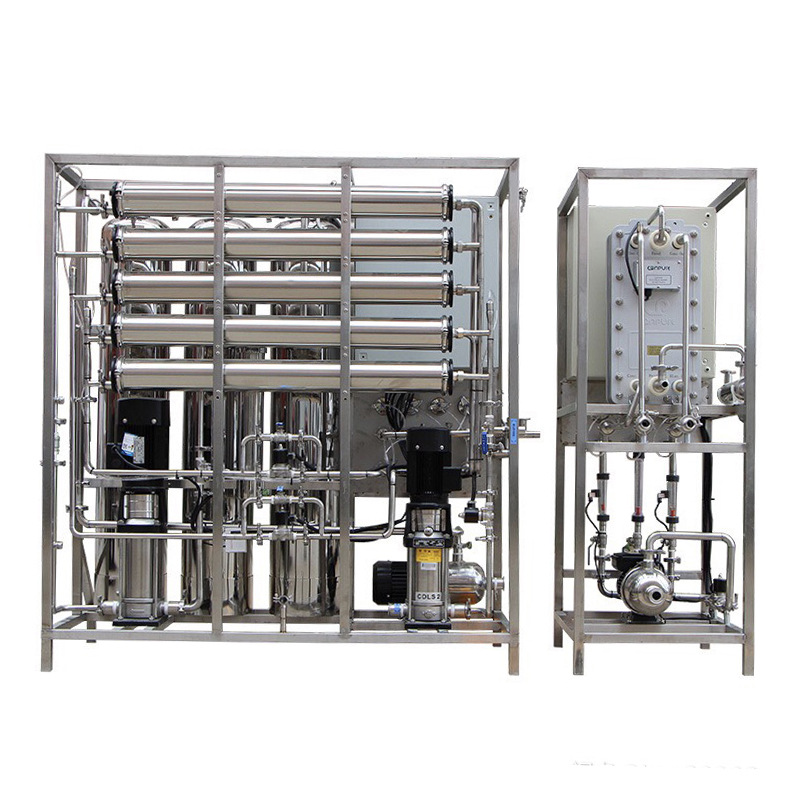

Customized Stainless Steel Dual-Stage RO Reverse Osmosis System – Integrated Ultrapure & Deionized Water Production Equipment

Ultrapure & Deionized Integration

Water production process: primary reverse osmosis

Water production: 0.5 tons/hour (can support customization)

Model: CR-RO1-0.5TH

Produced water quality: conductivity: 0.055µS/cm~10µS/cm; resistivity: 1Ω·m~18.2Ω·m

Floor area: more than 5 square meters

Scope of application: Semiconductor and electronics industries, biological and pharmaceutical industries, consumer goods and cosmetics industries and other industries that require high water purity

Product overview:

1. The equipment configuration adopts pretreatment + reverse osmosis main engine, which can effectively remove various salts and impurities, produce water efficiently, meet water quality standards, and low operating costs

2. AI fully automatic operation, with safety protection devices such as water shortage protection and low pressure protection

3. Complete set of configuration, integrated structure, small footprint, easy installation and use

4. Real-time online detection and display of raw water quality and pure water quality, so that the water quality can be seen and more assured

5. Our company adopts the Kanpur EDI module, which does not need to add salt, does not need concentrated water circulation, simplifies the system, improves current efficiency, and reduces operating costs

6. You can choose to import high-precision Dow RO reverse osmosis membrane or domestic membrane, the filtration accuracy can reach 0.0001 microns, and the pure water can be drunk directly

7. Southern vertical pump pressurization, intelligent water protection system, more convenient to use

8. Each product is processed through 58 processes. From the procurement of raw materials to the quality inspection of the final product, every link has been strictly checked to ensure the quality of the finished product

Water production process:

Raw water tank → raw water pump → quartz sand filter → activated carbon filter → softening resin exchanger → precision filter → primary high pressure pump → primary reverse osmosis membrane → primary pure water tank → secondary high pressure pump → secondary reverse osmosis Membrane → secondary pure water tank → EDI booster pump → EDI system → ultrapure water tank

Water purification site installation and commissioning engineering drawing

Applicable industries of reverse osmosis pure water equipment system

◆GMP medicine: in vitro diagnostic reagents, medical equipment, surgical utensils, laboratory pure water, etc.

◆Battery industry: storage battery, lithium battery, solar battery, etc.

◆Electroplating industry: metal plating, plastic plating, cooling lighting, etc.

◆Cosmetics industry: skin care products, toiletries, hair dyes, wet wipes, masks, etc.

◆Electronic industry: aluminum foil, liquid crystal screen, transistor, display tube, electron tube, etc.

◆High-purity water for glass coating, water for cleaning glass products, water for cleaning lamps, etc.

◆Cleaning industry: coating of glass products, lamps, electroplating preparation, electrophoretic paint preparation, paint preparation, ultrasound, etc.

According to water quality requirements, adopt suitable industrial process and equipment materials

| Water Quality | Water Treatment Process | Filtration Tank Material | Pipeline Material |

|---|---|---|---|

| Conductivity ≤ 10us/cm | Primary Reverse Osmosis (RO) | Fiberglass Reinforced Plastic (FRP) / Stainless Steel | UPVC / 304 Stainless Steel |

| Conductivity ≤ 5us/cm | Secondary RO | Fiberglass Reinforced Plastic (FRP) / Stainless Steel | UPVC / 304 Stainless Steel |

| Conductivity ≤ 2us/cm | Secondary RO | 304 Stainless Steel / 316 Stainless Steel | UPVC / 304 Stainless Steel / 316 Stainless Steel |

| Conductivity ≤ 1us/cm | Resistivity ≥ 1Ω·m | Primary RO + EDI | Fiberglass Reinforced Plastic (FRP) / Stainless Steel |

| Conductivity ≤ 0.067us/cm | Resistivity ≥ 15Ω·m | Secondary RO + EDI | Fiberglass Reinforced Plastic (FRP) / Stainless Steel |

| Conductivity ≤ 0.055us/cm | Resistivity ≥ 18.2Ω·m | Secondary RO + EDI + Polishing | Fiberglass Reinforced Plastic (FRP) / Stainless Steel |

Operation interface diagram:

Water purification equipment system service process

Water purification and pure water equipment system product service

① After-sales service

⑴ The whole process data from design to production, operation and after-sales will be stored free of charge for a long time.

⑵ Lifelong tracking of equipment operation status, SMS and phone calls to remind customers to replace consumables, provide free technical analysis services for equipment operation records, and judge system operation status to prevent problems before they happen.